Mon - Sat: 10am - 6pm

Mon - Sat: 10am - 6pm

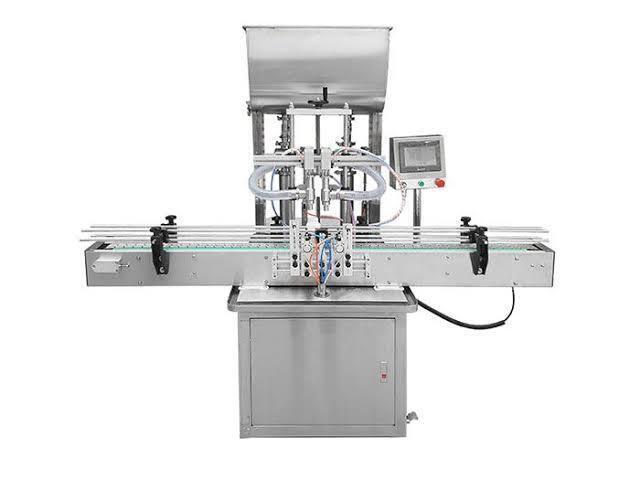

Semi Automatic Liquid Filling Machine

Product Details:

- Product Type Liquid Filling Machine

- Material Stainless Steel

- Automatic Grade Semi-Automatic

- Drive Type Electric

- Color Silver

- Click to View more

Semi Automatic Liquid Filling Machine Price And Quantity

- 1 Piece

Semi Automatic Liquid Filling Machine Product Specifications

- Silver

- Stainless Steel

- Liquid Filling Machine

- Semi-Automatic

- Electric

Semi Automatic Liquid Filling Machine Trade Information

- Ankleshwar , Gujarat

- Days after Acceptance (DA) Cheque

- Transport

- Eastern Europe Middle East Australia Western Europe Africa Central America South America Asia North America

- All India

Product Description

A machine made to partially automate the process of filling containers with liquid items is known as a semi-automatic liquid filling machine. During the filling process, some operator involvement is necessary. In sectors including food & beverage, pharmaceuticals, cosmetics, and chemicals where accurate and effective liquid filling is necessary without the need for completely automated operations, these devices are frequently employed.

A semi-automatic liquid filling machine typically has the following main traits and qualities:

1. Operator control: An operator starts and oversees the filling process. Typically, they start the filling cycle, keep an eye on things, and handle the containers by hand.

2. Filling mechanism: To move the liquid from a reservoir or hopper to the containers, the machine uses a filling mechanism, such as a piston, peristaltic pump, or gravity flow. The filling cycle is started by the operator after the container is placed beneath the filling nozzle.

3. Handling manual containers: In a semi-automatic machine, it is the operator's job to feed the containers under the filling nozzle and take them out after they are full. Positioning the container, starting the filling cycle, and releasing it after the necessary volume has been attained are examples of manual handling chores.

4. Filling parameters can be changed on the machine to fit various container sizes or filling requirements. Filling parameters can be changed including volume or dosage, filling speed, and nozzle height.

5. Control panel: The machine's settings can be controlled and altered by the operator using the control panel. It might have controls for cycle timing, filling volume, and other important variables.

6. Semi-automated features: While physical involvement is necessary throughout the filling process, some semi-automatic devices may have extra features to increase productivity. They might have a sensor-based mechanism or a foot pedal, for instance, that activates the filling cycle when a container is placed beneath the nozzle.

7. Versatility: Bottles, jars, cans, and pouches are just a few of the several types of containers that semi-automatic liquid filling machines can handle.

Semi-automatic liquid filling machines provide a flexible and economical solution for smaller-scale production or operations where operator involvement and flexibility are sought. They strike a compromise between manual control and automation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Call Me Free

Call Me Free